Workshop on Additive Manufacturing

Workshop on Additive Manufacturing

13-15th May 2019

Bundesanstalt für Materialforschung und –prüfung (BAM), Berlin, Germany

Location

Bundesanstalt für Materialforschung und -prüfung (BAM)

Unter den Eichen 87

12205 Berlin

(Ludwig-Erhard-Saal)

Organized by

Bundesanstalt für Materialforschung und -prüfung,

Department Non-destructive Testing

Workshop on additive manufacturing

13th Mai – 15th Mai 2019, Bundesanstalt für Materialforschung und -prüfung (BAM), Berlin

Scope

This workshop on additive manufacturing will have 2 parts. On the first day, we will present the actual research from BAM on additive manufacturing, focusing on 2 projects, namely AGIL and ProMoAM. The AGIL project looks into the aging phenomena in Additively Manufactured 316L, produced via PBF, LMD and WAAM, using a wide spectrum of approach from powder to specimen failure. The project will present microstructure, defects and residual stress characterization through to mechanical testing and simulations. The project ProMoAM closely related to AGIL and is focused on the in-situ monitoring of the build processes using the mentioned techniques. The goal is to adapt different NDT techniques that are well established at BAM to the online monitoring of metal additive manufacturing and to compare and correlate their results to find and possibly quantify defects in the built parts. The suitability and complementarity of techniques such as thermography, optical tomography, eddy current testing, optical emission and absorption spectroscopy photoacoustic, X-ray backscattering and laminography are examined.

The other 2 days will be dedicated to disseminating the results from technical work packages from the MetAMMI (Metrology for Additively Manufactured Medical Implants) project. The scientific and technical objectives of this project were:

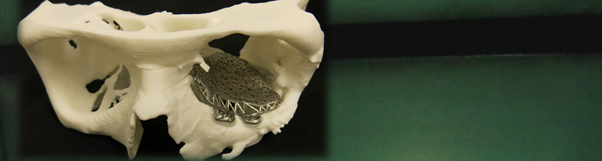

- To fabricate and characterise industrial medical implants, guides, and standard objects using destructive and non-destructive techniques (such as THz-CT, and XCT) and produce a good practice guide on the correct choice of characterisation technique. The implants, guides and standard objects will be made using different AM processes from materials such as polymers, ceramics, and metals and will be dense or lattice structures.

- To validate non-destructive characterisation techniques, develop traceable measurement capabilities and quantify dimensional measurement errors in the whole process of personalised body part replication and standard production parts including image analysis.

- To provide feedback to the manufacturing chain that enables process chain corrections to be implemented and manufacturing chain monitoring to be demonstrated. This will be done with the following:

- Metrology protocols that identify geometrical deviations between numerical model and part manufactured in the process chain;

- Correlation of the geometrical deviation to their origin to optimise the process for personal and mass produced implants and guides.

- To quantify the build-up of errors from each part of whole implant and guide manufacture chain from medical imaging to clinical use.

- To facilitate the take up of the technology and measurement infrastructure developed by the project by the measurement supply chain (accredited laboratories, instrumentation manufacturers), standards developing organisations (ISO/TC261, CEN/TC438, ISO/TC119, etc.) and end users (implant manufacturers and clinicians)

Topics covered

Agil & PromoAM:

- In-situ monitoring of AM processes using different techniques

- Correlation and data fusion for different in-situ monitoring techniques

- AM materials characterisation with cradle to grave approach

MetAMMI:

- Dimensional metrology for additive manufacturing for human body part replication

- Procedures for dimensional measurements of AM implants and their error assessment

- Report on the design, the traceable characterisation (surface and dimension) and the use of several reference standards for characterisation/ clinical phantoms

- Good practice guide on the correct choice of characterisation technique depending of the level of accuracy needed and the type of measurement required

- Surface roughness descriptors

- Good practice guide for medical image acquisition and analysis

- Good practice guide for the medical device industry to be able to identify geometrical deviations to enable process chain corrections to be implemented

- Report on examples that demonstrate full manufacturing chain monitoring for AM of implants and guides

- Report on case studies demonstrating the errors related to each manufacturing step from medical imaging to patient application

Partners

Collaborators from the MetAMMI project: https://projects.lne.eu/jrp-metammi

Workshop in 2019

Date: 13th Mai – 15th Mai 2019

Duration: 3 days

Venue: BAM (Ludwig-Erhard-Saal), Unter den Eichen 87, 12205 Berlin, Germany

Language: English

Cost: Registration is free

Size: limited to 100 participants

Local Organization

Phone: +49 30 8104-1859, email sekretariat-8.5@bam.de.

Registration

The registration for the AM Workshop 2019 is free but limited to 100 participants.

All cancellations need to be sent by mail to sekretariat-8.5@bam.de.