Workpackages

WP1: Realisation of AM implants and guides, and traceable standards

WP leader: DTU

Partners: LNE, BAM, NSAI, PTB, VTT, Aalto, DTI, CNRS, Lithoz, Medicrea, SKBS, U. Austria, Bego, PaS

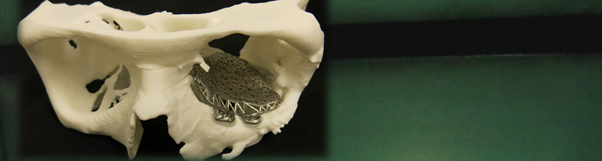

The aim of this work package is to provide industrial medical implants and guides, as well as traceable standard objects, fabricated with different AM processes such as SLS, EBM, SLA, FDM or BJ, from materials such as polymers, ceramics, or metals. Dense or lattice structures, that may contain inner structures, on metals, polymers and ceramics will also be investigated. The main result of this work package is to provide devices and standards to be characterized throughout the project. The main challenges of the WP are related to the manufacture of the parts to fulfil medical specifications in terms of dimensional, geometrical, and surface accuracy as well as material quality.

- Task 1.1 : Case studies of devices and standards

- Task 1.2 : Design of devices and standards

- Task 1.3: Fabrication of devices and standards

WP2: Characterisation of AM implants and guides, and traceable standards using non-destructive and destructive techniques

WP leader: PTB

Partners: LNE, BAM, DFM, DTU, NSAI, VTT, Aalto, FAU, CNRS, UNOTT, U. Austria, Lithoz, Medicrea

The aim of this work package is to characterise the medical implants, guides, and standard objects developed or provided in WP1 and the implants used for the case studies in WP5. The results of this work package are needed in WP3-WP5. The characterisation includes inner and outer geometry, surface characteristics, porosity, density, defects, and mechanical properties. For this, volumetric methods (XCT, THz-CT), methods detecting the whole object surface (tactile probes, optical sensors), porosity and density measurements (gas pycnometer, Archimedes’ method), defect detection (destructive and non-destructive), surface properties measurement techniques (tactile and optical) and mechanical tests will be applied. The main challenges of the WP are the special characteristics of AM parts (e.g. high roughness, density variations, internal defects, porosity) and the variety of characteristics to determine.

- Task 2.1: Volumetric characterisation

- Task 2.2: Optical and tactile characterisation

- Task 2.3: Density and porosity determination

- Task 2.4: Mechanical tests, destructive and non-destructive testing

WP3: Uncertainty and errors on reference object dimensional metrology

WP leader: BAM

Partners: LNE, DFM, DTU, NSAI, PTB, VTT, Aalto, DTI, FAU, CNRS, Medicrea, SKBS, U.Austria, UNOTT, Lego, PaS,

The aim of this work package is to validate non-destructive characterisation techniques, develop traceable measurement capabilities and quantify dimensional measurement errors (from <1 m powder particle size up to 400 µm) in the whole process of personalised body part replication and standard production parts.

The key challenges here are to develop quantitative tools for:

1- extraction of most important microstructural features (not yet available in current commercial software packages);

2- simulation of the influence of surface roughness with length scale below the resolution of CT equipment;

3- extraction of quantitative surface data for further use (dimensional metrology, simulations).

Measurements, simulations, and calculations will be used to quantify the metrological and characterisation capability of each technique, with the vision of identifying the best suited technique for each part and material.

This also makes it possible to objectively compare the measurement capabilities of the different systems (XCT, CMM, THz-CT) for measurements of AM medical devices. The error evaluation methodology, as well the metrological capabilities developed in this WP will serve as a tool to qualify the manufacturing chains in WP4 and to quantify the clinical cases worked out in WP5. A most important part will be dedicated to the extraction of quantitative data from the 3D data available from different techniques. To the aim of quantifying images, the standard artefacts from WP1 (as opposed to industrially or clinically relevant ones) will be needed, with simpler geometries and/or materials

- Task 3.1: Image analysis

- Task 3.2: Simulations

- Task 3.3: Evaluation of uncertainties; Quantification of dimensional measurement errors

- Task 3.4: Uncertainty of surface extraction from medical and industrial volumetric XCT data

WP4: Manufacturing chain-errors (Patient image to final AM part)

WP leader: BAM

Partners: DFM, DTU, LNE, NSAI, PTB, VTT, Aalto, DTI, FAU, CNRS, Lithoz, Medicrea, SKBS, U. Austria

The aim of this WP is to use metrology to provide a feedback to the manufacturing chain, and to provide information to formulate rules of design. In that sense, WP4 is building the basis for future works on the optimization of the process chain for AM of implants and guides.

In the focus of this WP are geometrical deviations between model and part manufactured. WP4 starts from the metrological validation of AM parts and compares 3D reconstructions (from scans) with the 3D model of the parts. AM parts do exist as semi-finished of finished parts at various stages within the AM process chain. Metrology will help to identify, where exactly geometrical distortions relative to the model are generated and how and at which stage in the process chain corrections need to be implemented. WP3 analyses the deviations between medical device and 3D model. With this information WP4 traces back their origin in the process chain. Medical imaging and 3D model reconstruction is provided by protocols and methodologies from WP2 and 3.

Strategies for quality control sampling and probing schemes will be different for the additive manufacture of individualized parts and the mass production of complex parts. For mass production a particular AM process can be iteratively improved, while for production of a custom device the aim is to be “first time right”.

– The difference between WP4 and WP5 is that, while WP5 also goes into the process chain, WP4 is specifically dedicated to identifying metrology protocols for the detection and quantification of defects. The aim of these protocols is twofold: to efficiently and precisely identify deviations in single parts and especially in mass produced parts

– to correlate typical deviations to their origin in the process chain, thus providing important information to the manufacturer to optimize the process.

- Task 4.1: Definition of possible deviations from the model geometry

- Task 4.2: Replication of geometrical deviations in a standard reference part

- Task 4.3: Elaboration of protocols for the identification of deviations

WP5: Clinical case studies

WP leader: VTT

Partners: PTB, DTU, Aalto, DTI, Medicrea, SKBS, U. Austria, UNOTT, Bego, PaS,

The aim of this work package is to quantify the build-up of errors from each part of whole implant and guide manufacture chain from medical imaging to clinical use so that the confidence in AM can be improved. The typical steps in body part replication are:

- Medical imaging

- Segmentation of relevant tissues for 3D model reconstruction

- Selection of implant/guide material, type and structure

- 3D modelling for implant/guide and preoperative model

- Additive manufacturing and finishing of printed parts

- Clinical use

Several different clinical applications have been selected for studies in which whole implant manufacture chain will be performed and evaluated. In some cases several steps may be only accessible in combination. In this case the combined uncertainty budget of these steps will be assessed. In all of the cases implant and guide efficiency will be evaluated.

- Task 5.1: Medical imaging and 3D model reconstruction

- Task 5.2: Design and additive manufacture of the implants and guides

- Task 5.3: Evaluation of the error propagation in clinical case studies

WP6: Creating impact

WP leader: LNE

Partners: All partners

The aim of this work package is to create maximum impact though dissemination, publication, and exploitation of the project results, including some appropriate training for end users. The WP will maximise the value and impact of the scientific work delivered by the JRP through a combination of interaction with the major stakeholders and end-users, including two-way information exchange, input into European standards, assisting Member States to comply defensibly with existing legislation, providing evidence-based outcomes to help formulate improved policy and metrics, practical help and training for end users, and facilitating commercial exploitation of the results by European-based businesses.

- Task 6.1 Knowledge transfer

- Task 6.2 Training

- Task 6.3 Uptake and exploitation

WP7: Management and coordination

WP leader: LNE

Partners: All partners

The aim of this work package is to ensure high quality and efficient project implementation and management. All JRP-Partners will participate through attendance at project meetings and contribution to the reporting.

- Task 7.1: Project management

- Task 7.2: Project meetings

- Task 7.3: Project reporting